Bolivia sets high hopes on its lithium industry

Bolivia, one of the poorest countries in Latin America, has began shipping lithium to China in what is considered the first step towards fulfilling its ambitions to becoming the world’s No. 1 exporter of the commodity, used in high tech devices such as smart phones and electric cars, as well as in the pharmaceutical industry.

With a price tag of barely $70,000, Bolivia’s lithium shipment to China is being seen more like a symbolic transaction than a financial breakthrough for the country.

Those first 10 tonnes of lithium carbonate were extracted from a pilot plant at the country’s salt flats, located in the southwestern region of Uyuni, local newspaper EFE News Agency reports (in Spanish).

But with a price tag of barely $70,000, the move is being seen more like a symbolic transaction than a financial breakthrough for the country, which expects to multiply the figure into millions of dollars by 2020.

Lithium, frequently referred to as “white petroleum,” drives much of the modern world, as it has become an irreplaceable component of rechargeable batteries used in high tech devices.

Better Lithium Batteries to Get a Test Flight

The batteries should last twice as long as comparably sized rivals.

by Richard Martin August 23, 2016

Scientists have known for decades that lithium-metal batteries offer a powerful combination of energy density and compactness. Unfortunately these batteries also present challenges: they are difficult to recharge and they have an unfortunate tendency to burst into flame.

Boston-based startup SolidEnergy Systems, spun out of the MIT lab of Donald Sadoway in 2012, claims to have solved these problems with a novel anode structure and hybrid electrolyte. Qichao Hu, SolidEnergy’s founder, first showed a prototype last fall that is half the size of an iPhone 6 battery and offers more battery life per charge. The company says it will sell batteries for smartphones by early next year, and for electric vehicles in 2018. First, though, it’s going after a more specialized market: drones.

Specifically, Hu points to the high-altitude drones and balloons being developed to provide Wi-Fi in remote areas. “They need to be powered by batteries, but the current lithium-ion battery lifetime is very short and the batteries are heavy.” SolidEnergy’s new battery, he says, provides “the same capacity at half the volume and half the weight.”

Last fall SolidEnergy showed a prototype that’s half the size of an iPhone 6 battery but offers more battery life per charge.

Selling batteries for drone makers could be a clever means of entry for a new battery company, many of which have had trouble competing with established battery providers like Panasonic, which has a multi-billion-dollar contract to supply electric-car maker Tesla with batteries. But while SolidEnergy’s technology is novel, it is still unproven at the scale necessary to grab a portion of the growing drone market, to say nothing of cell phones and electric vehicles.

Lithium-ion batteries, which are found in the preponderance of today’s cell phones and electric vehicles, use a variety of lithium-oxide compounds for the cathode, and a non-lithium material (usually graphite) for the anode. Lithium-metal batteries, on the other hand, use a metallic-lithium anode. It’s long been known that lithium-metal batteries offer higher energy densities, but their volatility makes them problematic.

SolidEnergy’s product is a lithium-metal battery that has a thin, high-energy anode made of lithium-metal foil, rather than the more common graphite. SolidEnergy’s key innovation, however, is in the electrolyte. To reduce the anode’s tendency to become “mossy,” or covered in bumps that tend to cause short circuits, Hu developed a hybrid electrolyte that consists of a thin, solid coating on the anode, which protects the lithium metal from reacting with the volatile electrolyte, and a liquid electrolyte in the cathode, which helps the battery function at lower temperatures.

Read MoreFMC contract underlines rising battery demand for Lithium

The lithium market received a boost after FMC said it planned to double its output of battery raw material lithium next year, in a sign the largest producers are increasing supply to meet demand from electric carmakers.

The Philadelphia-based chemical company, one of the world’s four largest producers of lithium, said it would accelerate expansion of lithium hydroxide as a result of a “new multiyear supply agreement with a major manufacturer of electric vehicles”.

Lithium could be the new gasoline as Tesla stokes demand

Struggling with toxic air pollution levels, China is looking to alternative fuels with renewed urgency. Battery grade lithium prices have spiked in the country since 2015, with the domestic rate of electric vehicle production reaching 37,000 units through May; its highest point in the year so far according to the latest reports. The appetite for electric vehicles is one that is being increasingly endorsed by government authorities as subsidies and tax breaks are hastily introduced to offset the more expensive retail prices. Bloomberg estimates that 35% of light vehicles sold will be electric by 2040, generating a battery market worth a projected US$250 billion.

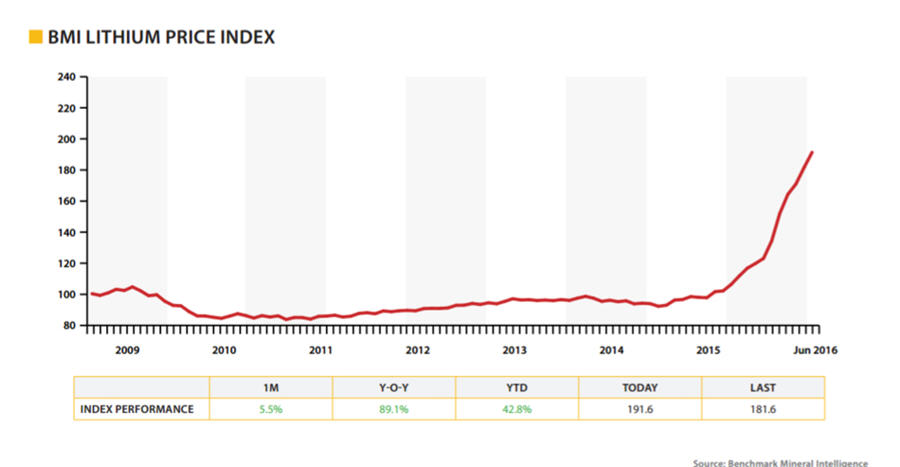

With the swell of recent battery orders, lithium prices climbed another 5.5% through June 2016. Panasonic, a leading provider in the industry, predicts that it will double battery sales by 2020. Data from Benchmark Mineral Intelligence showed a concurrent demand story: Lithium prices are up 43% so far this year, while the cost of intermediate refining product, lithium carbonate, jumped 4.3% through June 2016. Analyst expect prices to continue inflating throughout the rest of the year as industry majors struggle to expand their lithium output and gain access to raw materials.

Tesla has invested heavily in the renewable energy source. Elon Musk’s $5 billion Gigafactory development in Nevada is only 15% completed, but the company estimates it will be able to churn out half a million electric vehicles annually by 2018.

Musk has recently voiced aspirations to expand his lithium battery production globally, sighting Europe, India and China as potential factory locations. Other major car manufacturers are quickly joining the electric vehicle rush, scrambling to incorporate the electric batteries into their production line. In Germany, Daimler has committed US$550 million to creating a second lithium-ion battery plant, while GM and Nissan are also eyeing expansion deals.

Read More